Ultimate Source for Advanced Automobile Tool Cluster Repair Service Strategies

In the world of modern vehicle maintenance, the details of instrument cluster repair stand as an important aspect of ensuring the ideal performance of a vehicle (tahoe instrument cluster repair). As technology breakthroughs, so do the intricacies of these vital elements, requiring an extensive understanding of advanced fixing techniques. With a myriad of potential concerns that can arise within tool clusters, having a reliable source that supplies thorough assistance on troubleshooting and rectifying these challenges becomes critical. By exploring the tools required, typical troubles came across, and step-by-step repair service methods, one can equip themselves with the knowledge needed to browse the elaborate world of car instrument cluster repair with self-confidence and accuracy.

Relevance of Advanced Instrument Collection Fixing

Understanding the importance of advanced instrument collection repair work is vital for maintaining the capability and accuracy of modern-day automobile systems. The tool collection serves as the hub of details for motorists, presenting critical data such as rate, gas levels, engine temperature, and warning indicators. With the innovation of technology, instrument collections have progressed to integrate complex digital elements and electronic screens, making repair services a lot more elaborate and specialized.

Proper repair and maintenance of the tool cluster are essential for making certain the safety and security and efficiency of the automobile. Concerns with the instrument collection can lead to inaccurate readings, breakdowns in crucial systems, and safety and security hazards when driving. Advanced tool cluster fixing techniques involve identifying digital mistakes, recalibrating sensors, and reprogramming software application to recover optimum efficiency.

Devices and Devices Needed

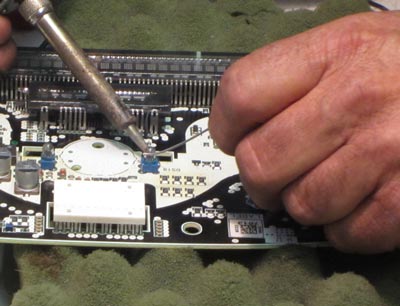

To effectively address the intricate repair requirements of contemporary vehicle instrument collections, a specialized collection of devices and devices is vital. A few of the trick devices needed for advanced car tool cluster repair work include precision screwdrivers, trim removal tools, soldering tools, electronic multimeters, and diagnostic scanners. Precision screwdrivers are vital for dismantling the collection without triggering damage. Cut elimination devices help in safely prying off panels and bezels. Soldering devices is required for fixing damaged links or replacing components. Digital multimeters are used to measure voltage, continuity, and resistance throughout analysis procedures. Diagnostic scanners are crucial for recognizing and repairing digital problems within the instrument cluster. Additionally, having a top quality blowpipe, desoldering pump, and solder cord is very important for carrying out elaborate soldering job. Correct illumination, a magnifying glass, and a tidy workspace are likewise important for making certain accuracy and accuracy throughout repairs. By having these specialized devices and equipment available, service technicians can efficiently diagnose and settle complex issues in vehicle tool clusters.

Typical Problems and Solutions

Numerous typical problems often encountered in vehicle tool clusters can be successfully resolved with targeted options. One common issue is malfunctioning assesses, which might result from a malfunctioning stepper motor. To address this, replacing the stepper motor can restore accurate scale readings. An additional typical problem is flickering or dark lights on the tool cluster (tahoe instrument cluster repair). This can frequently be associated to a damaged bulb or inadequate links. By replacing the bulb or guaranteeing protected links, the lighting issue can be conveniently treated. In addition, a malfunctioning odometer or display screen is a regular problem. This can be due here to a faulty display screen system that requires to be changed to bring back appropriate capability. Periodic power or full failing of the tool cluster might stem from a blown fuse or wiring problem. Checking and replacing the fuse, along with checking the wiring for any damages, can assist resolve these power-related problems efficiently. By recognizing these typical issues and applying the appropriate remedies, car tool cluster functionality can be recovered successfully.

Step-by-Step Repair Work Guide

A methodical method to repairing and diagnosing auto instrument cluster problems is necessary for achieving effective and accurate results. To begin the repair work procedure, the initial step is to meticulously evaluate the instrument cluster for any kind of visible damage such as burnt-out light bulbs, split displays, or loose links.

Tips for Precautionary Upkeep

After conducting a comprehensive analysis scan and finishing necessary fixings on the car instrument cluster, executing normal preventative upkeep actions is critical to ensure long-lasting capability and optimal efficiency of the automobile's essential gauges and indicators. To start, it is important to routinely inspect the tool collection for any indications of wear, such as fading display screens or malfunctioning lights. Maintaining the collection clean from dust and debris can likewise protect against damage to delicate elements. Additionally, inspecting the links and electrical wiring for any type of indicators of deterioration or loosened links can assist avoid electric concerns that may influence the collection's efficiency.

Furthermore, upgrading the software application of the instrument collection when essential can make sure compatibility with any type of new functions or systems in the vehicle. It is likewise recommended to comply with the manufacturer's recommended maintenance routine and guidelines for the tool cluster to keep its durability. By including these preventative upkeep tips into your routine lorry treatment, you can aid prolong the lifespan and integrity of your vehicle instrument collection.

Conclusion

Finally, sophisticated automobile instrument collection repair methods are crucial for preserving the functionality of modern vehicles. By utilizing the correct devices and devices, addressing common concerns, and following a detailed repair work guide, professionals can successfully identify and deal with instrument collection issues. Implementing preventative maintenance techniques can aid lengthen the basics life expectancy of the instrument collection and prevent future problems from developing.

By exploring the tools required, common troubles came across, and detailed repair approaches, one can furnish themselves with the knowledge required to navigate the detailed world of car tool cluster repair work with self-confidence and accuracy.

A methodical approach to repairing and identifying automobile instrument collection problems is vital for attaining efficient and accurate outcomes. By following this detailed guide carefully, vehicle service technicians can successfully identify and fix tool cluster issues with precision and confidence.

In conclusion, advanced auto instrument collection fixing methods are necessary for preserving the performance of modern-day cars. By utilizing the correct tools and equipment, addressing common concerns, see this site and adhering to a detailed repair overview, technicians can successfully deal with and detect instrument cluster troubles.